Ambitious global onshore and offshore targets and sustainability issues for the Wind Turbine Blades market

11 April 2023

Ambitious global onshore and offshore targets and sustainability issues, will drive and impact the manufacturing and supply chain for the wind turbine blades market.

Our report published in March 2023, estimates the value of the global composite blade market at over €5 billion. The report quantifies the market, analyses its structure, and examines the changes which are underway. Additionally, it discusses the status of wind blade technology and the main sustainability threats and opportunities.

AMI Consulting estimates that global demand for materials (in weight) for the production of wind turbine blades grew at an average rate of 14.7% p.a. between 2017 and 2022. Demand growth has been particularly strong in Asia and North America.

The introduction of the new action system in China brought another installation rush, like that seen back in 2015. In 2021, this led to a 39% drop in new onshore installations. Likewise, new capacity additions in the US reached annual record-breaking levels in 2019 and 2020 because US wind projects had to come online by December 2020 to receive the full 2016 PTC (Production Tax Credit) value. Disruptions in the supply chain caused by the COVID-19 pandemic, the US onshore market experienced a drop in new installations in 2021. Some of these projects were delayed to 2022.

The industry continues its transition towards energy auction systems, a process that in some countries has not been a smooth experience. With the move towards auction systems, the need for manufacturers to maintain low cost of energy levels is more important than ever. The increased competition among wind turbine manufacturers continues to exert pressure on prices. The report provides a comprehensive review of the different commercial strategies adopted by OEMs and raw material suppliers to adapt to this competitive pressure.

Increased effort is being invested into blade designs to maximise power generation and reliability while minimising weight. This requires careful attention to materials, processing and blade design. To maximise generators’ return on investment, average blade size is getting longer. As blade length and weight grow, increased sophistication in blade design, materials and manufacture are required. The link between generating capacity and blade size is examined in the report. Increasing blade length has not only been driven by offshore wind energy growth but also to maximise wind capture of onshore wind turbines on low wind speed sites, specified at a lower power rating.

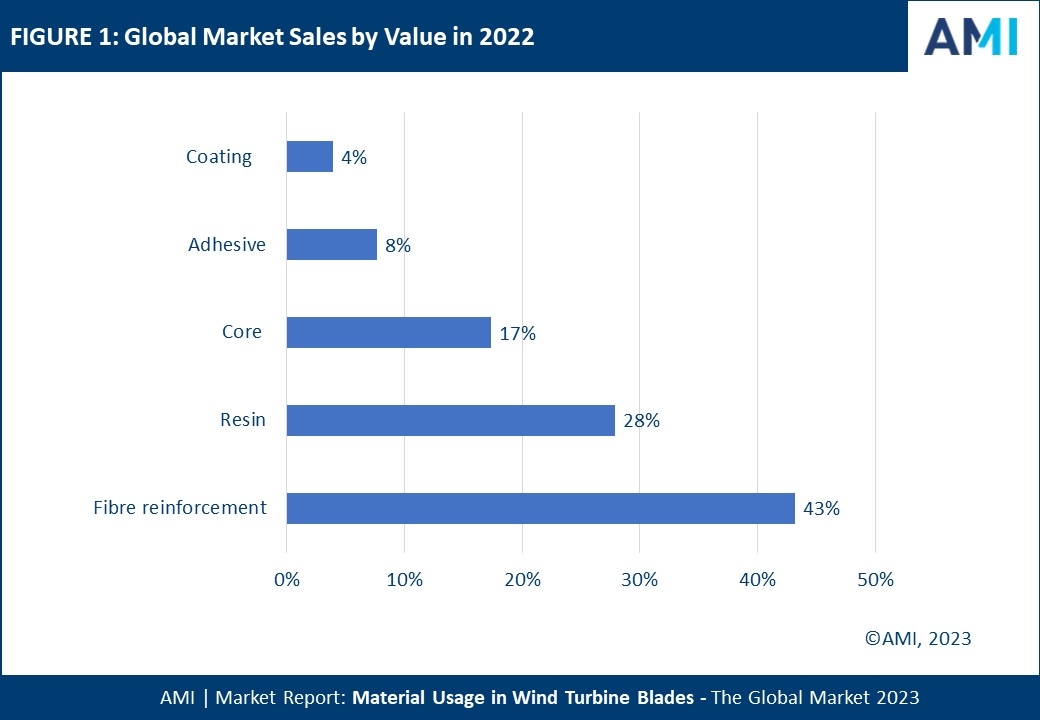

The production of longer blades is having a significant effect on material consumption for blade production both in terms of quantity and quality, accelerating demand for higher performance materials. At the same time, certain materials have been commoditised. The different market dynamics within each material group have brought very interesting material selection trends, not only around fibre reinforcement (where carbon fibre consumption increases), but also in other less obvious areas including core, adhesives or coatings. These trends have affected material suppliers’ market share as detailed in the report for each material, together with a comprehensive assessment of the pros and cons of the material alternatives available alongside a review of the material shortages experienced by the industry.

As wind turbines get larger and technical standards rise, so the financial bar is raised for blade manufacturers to compete leading to further market concentration. The wind turbine blades market has changed significantly in recent years as a result of this consolidation process that has reduced the number of players to the point that, during 2022, the top five blade manufacturers accounted for almost 60% of material demand by weight. This clear and addressable market volume makes it a very attractive market for material suppliers, even for commoditised materials, given the scale of these accounts. Consolidation has affected both onshore and offshore markets, but the onshore market continues to be significantly more fragmented than offshore.

Europe maintains technological leadership in this market. This is particularly relevant for offshore, which is expected to be one of the most important factors driving growth over the next few years. China’s position in the global industry is significant but can be hard to quantify. AMI Consulting has invested significant time and resources on understanding this region, bringing clarity in order to help subscribers gain critical insight into this key region.

The wind turbine blade industry is not an exception and sustainability and end of life has become in recent years one of the key areas for debate. In this edition, not only the issue of the end of life of blades approached but also an overview of the carbon footprint of the different materials available.

Wind turbines are designed for a lifetime about 20-25 years and from a Life Cycle Analysis (LCA) point of view are one of the best things that can be done for energy generation. On average it takes a matter of months (4-7) to claim back the carbon associated with their manufacture and so the environmental picture is very positive and rosy. However, as an industry we can’t be blasé about it and have to reduce waste, maximise production efficiency and start using responsible materials.

The majority of wind turbine systems are readily recyclable. They're made from materials like steel and concrete, which do have an established end of life. But the piece of the puzzle which is harder to close out are the blades. Typically, that is glass fibre reinforcing a thermoset resin, either epoxy or polyester resins that cure and which are therefore hard and can't be re-melted. The challenge is that even early blades are large, starting at 30 metres. Now they are beyond 110 metres with 130 metre long blades soon to be released. And that makes recycling and recovery hard. These materials were designed to stand 25 years to 30 years very rigorous service life in very harsh environments, which means that they're very hard to degrade and separate.

The topic of sustainability is a broad one, covering end of life, recyclability, use of recyclable and biomaterials, as well as waste. There have been a number of recyclable and recovery initiatives established over the last 2-3 years and these are set to grow in number and focus over the coming 3-5 years.

This report looks at the status of the various processes and progress of the consortiums looking at the issues from their different perspectives. It also looks at the sustainability landscape across the world, putting figures to the extent of the impending end-of-life issue and identifying the opportunities that exist.

By providing independent qualitative and quantitative analysis, subscribers to Material Usage in Wind Turbine Blades - The Global Market 2023 will gain a strong understanding of the scale of the market, its dynamics and the changing market share of the key participants.

For more information, please contact Brian Hinchliffe, Market Intelligence Sales Manager brian.hinchliffe@amiplastics.com